|

|

| |

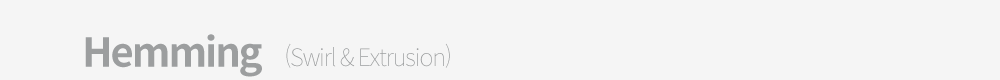

The hemming sealing is the sealer spread method used in bonding the inner and the outer panel of automobile.

The hemming sealant is spread along the outer space of the vehicle in the process of

bending/folding the inner and outer part of the flange,

and then is bonded thermally while the vehicle passes the electro-deposition dry oven.

As it is spread on the outer surface of vehicle, the appearance could be affected and, as a result,

the final quality of the completed product could be influenced seriously. Therefore, in this process, the accuracy is important.

|

|

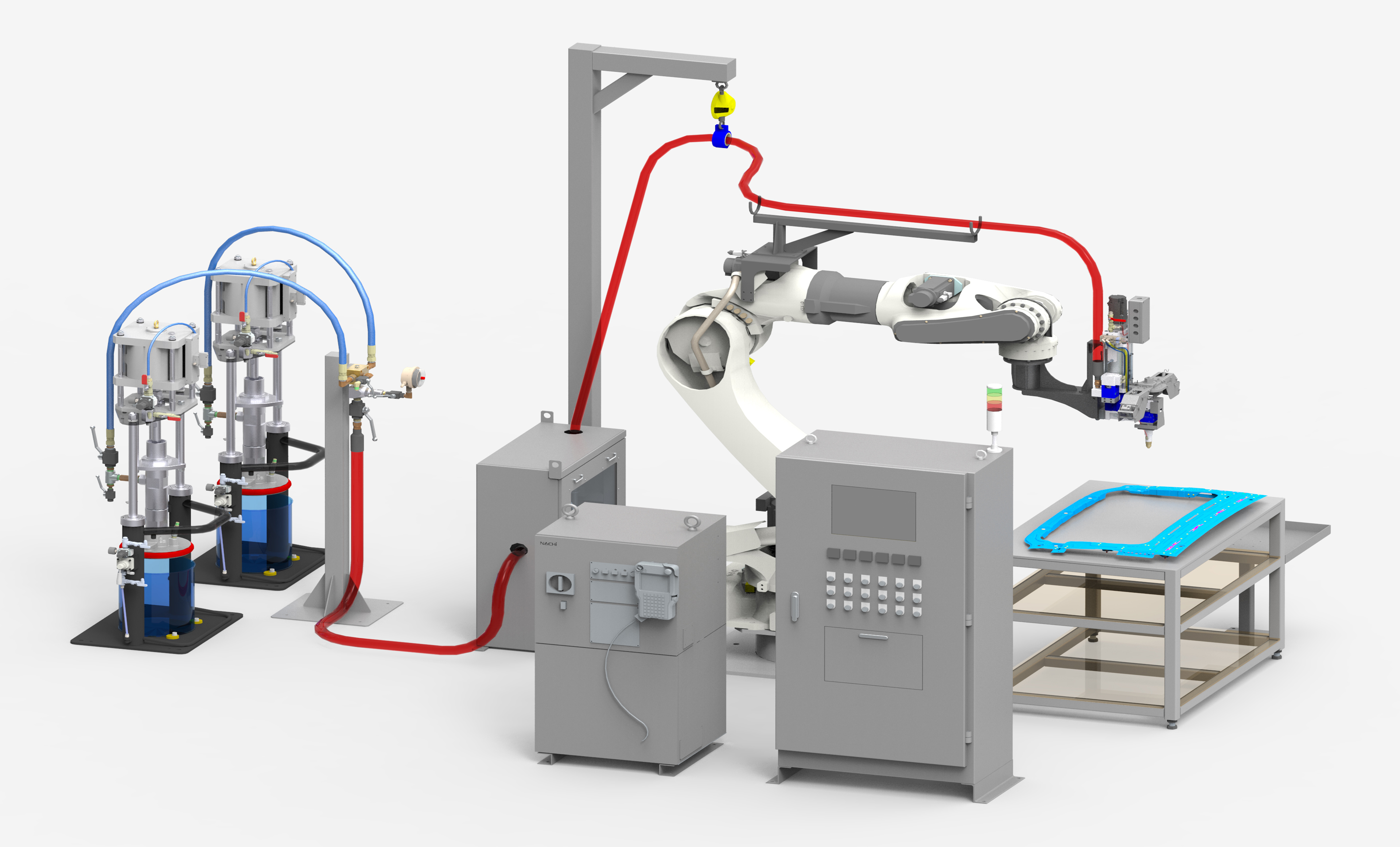

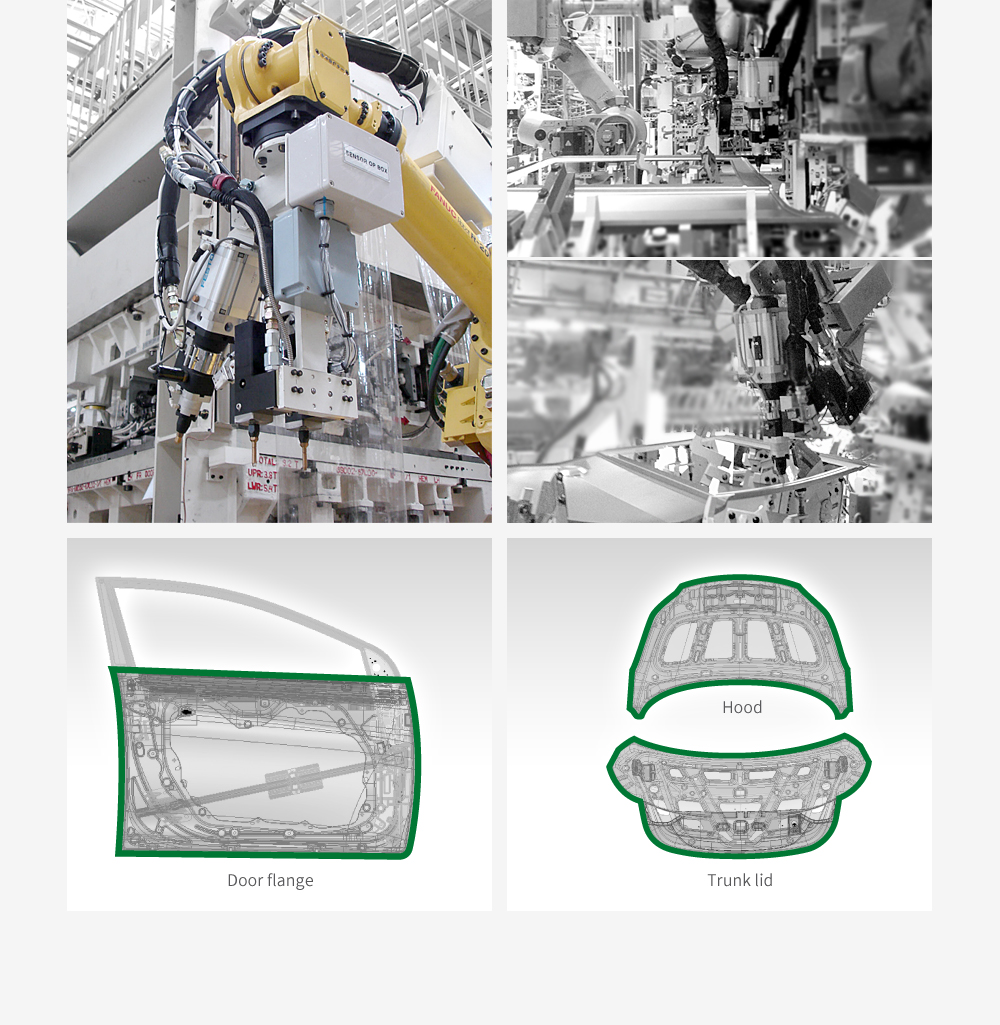

It is applied to various moving parts of automobile, displaying a powerful adhesive strength,

and is used in H/Flange part, such as hood, door et al, for the purpose of water tight and rust prevention. |

|

|

|

|

|

|

• Appearance of the sealant :

grey or black-colored adhesive

• Main component : epoxy resin

• Hardening rate : 98% or higher

• Viscosity : 400,000~900,000 cps

• Maximum working pressure : 300 bar

• Booster capacity : 25cc

|

|

• Reducing the welding-elimination process

• Enhancing the rust preventing function

• Enhancing the quality of panel and painting

• Improving the working conditions by

the dust elimination

• Saving the material and labor cost

|

|