| |||||

|

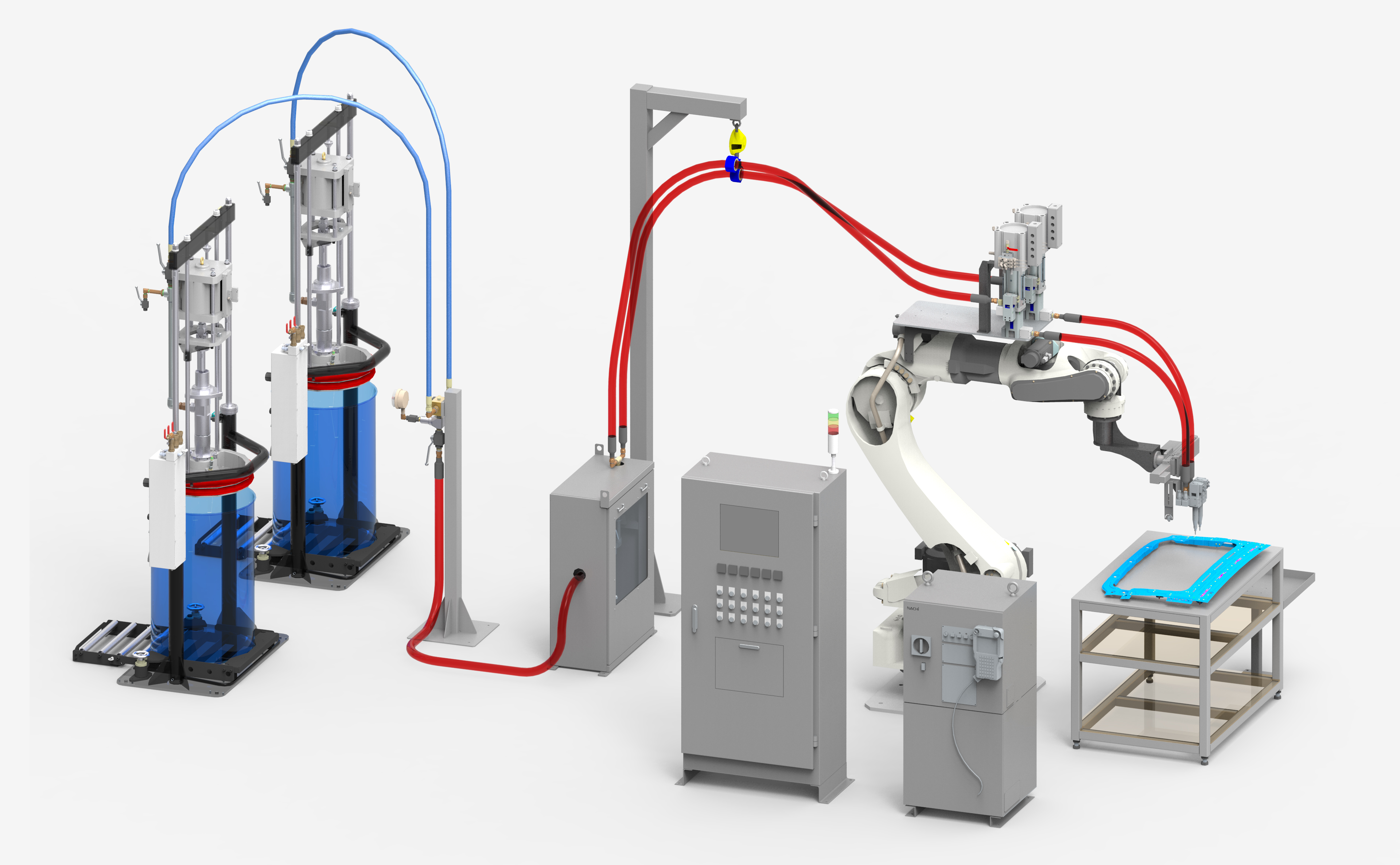

The sealer is the black-colored one-package paste-form product mixing curing agent, additives et al, including the synthetic rubber as the main component. The method of spot sealing enhances welding and rust-preventing function by using the sealer to which the conductive agent is added in order to prevent the strength reduction while welding, and is applied for water tight and rust prevention by spreading the sealer on various connection parts of panels and making it cured and bonded at the electro-deposition dry oven. * When the panels of automobile are connected, the sealer is applied for water tight and rust prevention by spreading on the inside of welding. | |||||

| |||||

|

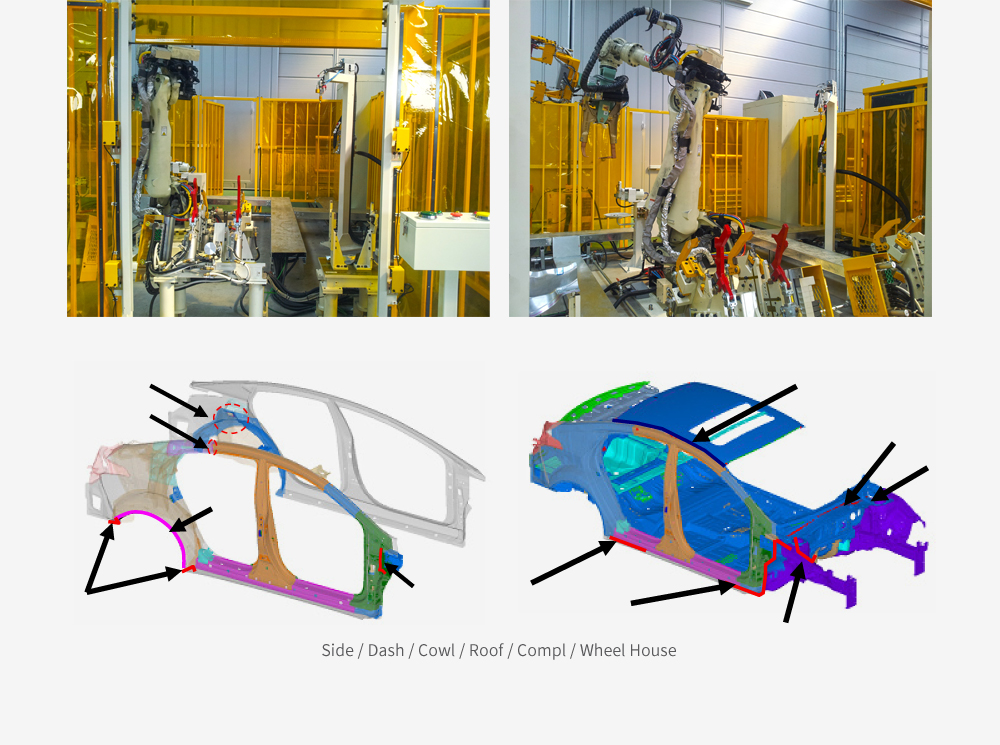

SIDE(LH/RH) / WHEEL HOUSE / DASH / COWL / FLOOR / OTHERS When connecting panels, spread the sealer on the inside of welding part. | |||||

| |||||

|

|

|

|||

|

• Appearance of the sealant : grey or black-colored paste • Main component : synthetic rubber • Hardening rate : 98% or higher • Viscosity : 2,000~3,000 cps • Maximum working pressure : 250~300 bar |

• Easy welding as using the sealant of high electric charge efficiency and electrical connectivity • Excellent efficiency of waterproof and anti-corrosion, owing to outstanding adhesive property • Outstanding rust prevention as the electro-deposition coating is formed on the surface of sealant • Easy work by using one-package paste • Safe from contamination in the pre-treatment process |

||||

| |||||