| |||||

|

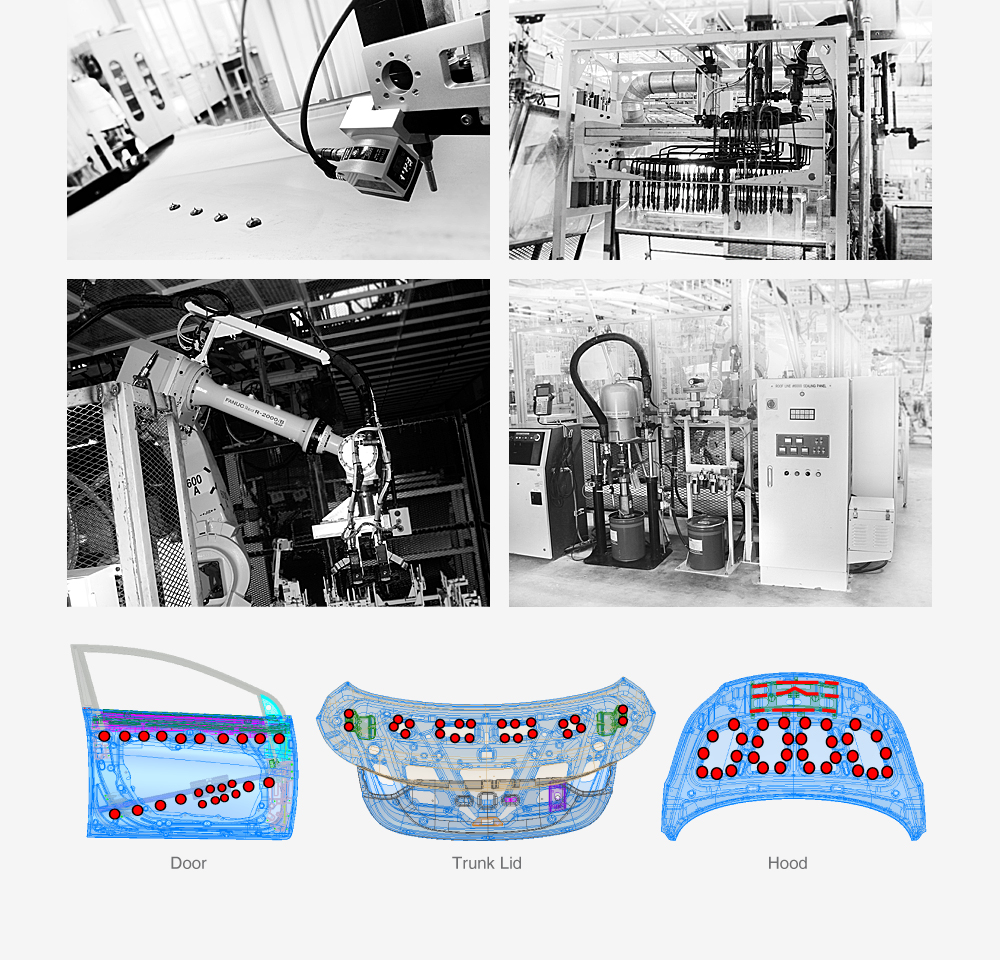

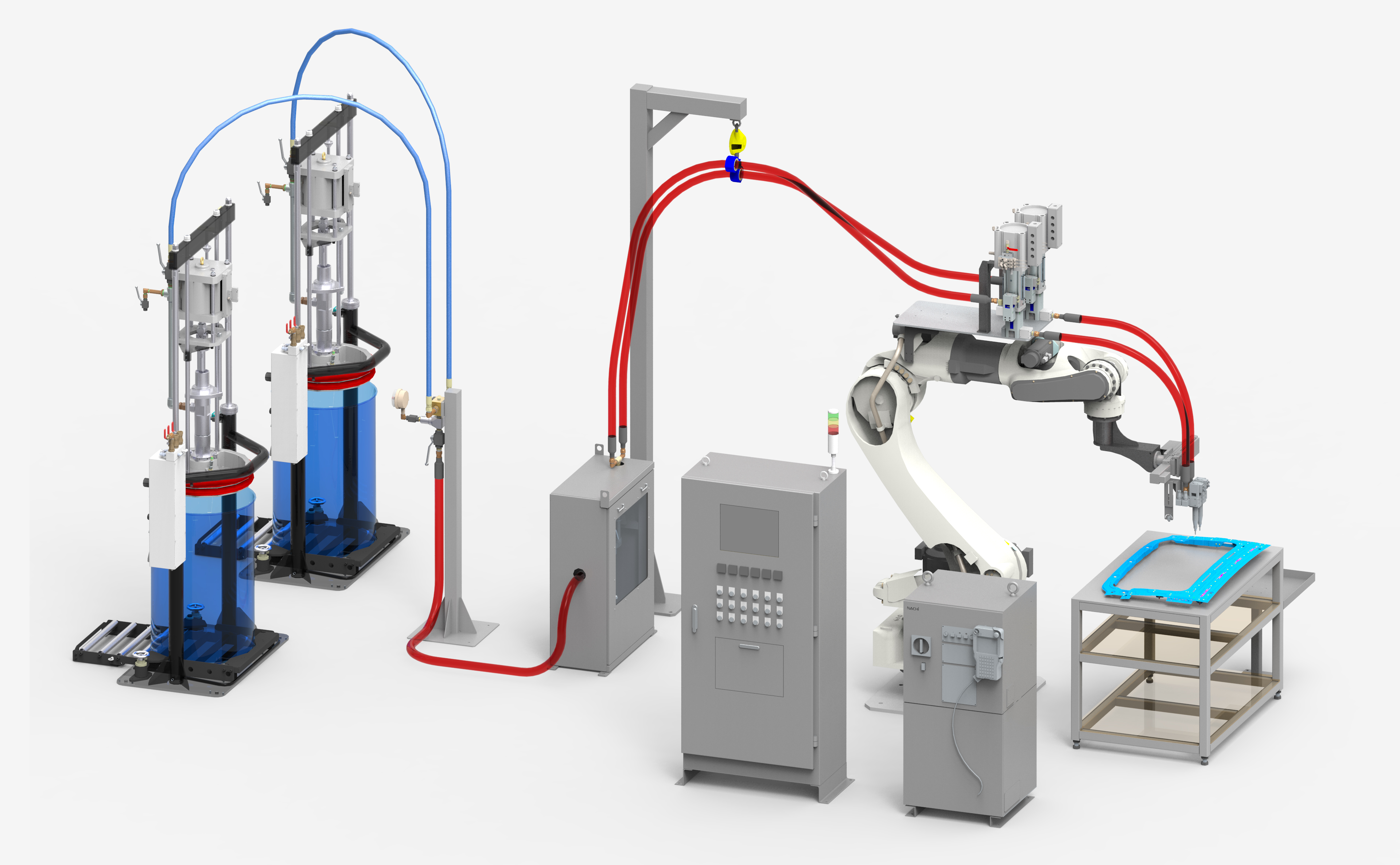

The mastic sealing is the one-package paste-form product mixing curing agent, additives, foaming agent et al, including the synthetic rubber as the main component. The method of mastic sealing is applied for uniform filling, bonding, and sound deadening by applying the mastic sealing to the part of which the gap is comparatively irregular using the foaming-typed mastic sealer foamed, cured and bonded when passing the dry oven. | |||||

| |||||

|

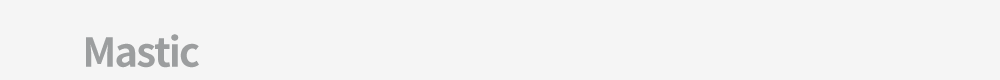

DOOR(FRT/RR) / HOOD / T-LID(TRUNK-LID) / T-GATE(TAIL GATE) / SIDE(LH/RH) / ROOF / B-B(BODY-BUILD) / OTHERS • Generally, applying the mastic sealing to the central point of the outer panel where the gap is irregular | |||||

| |||||

|

|

||||

|

• Appearance of the sealant : grey or black-colored adhesive • Main component : synthetic rubber • Hardening rate : 98% or higher • Foaming rate : 30% or higher • Maximum working pressure : 250~300 bar |

• Easy work by using one-package paste • Protected from fine dust even in case of big difference of panel owing to the foaming type • Economic owing to the bonding efficiency and outstanding water-proof/rust-prevention efficiency • Better rust-prevention efficiency than non-foaming type • Causing almost no dents by shrinkage when hardening owing to the foaming type |

||||

| |||||