| |||||

|

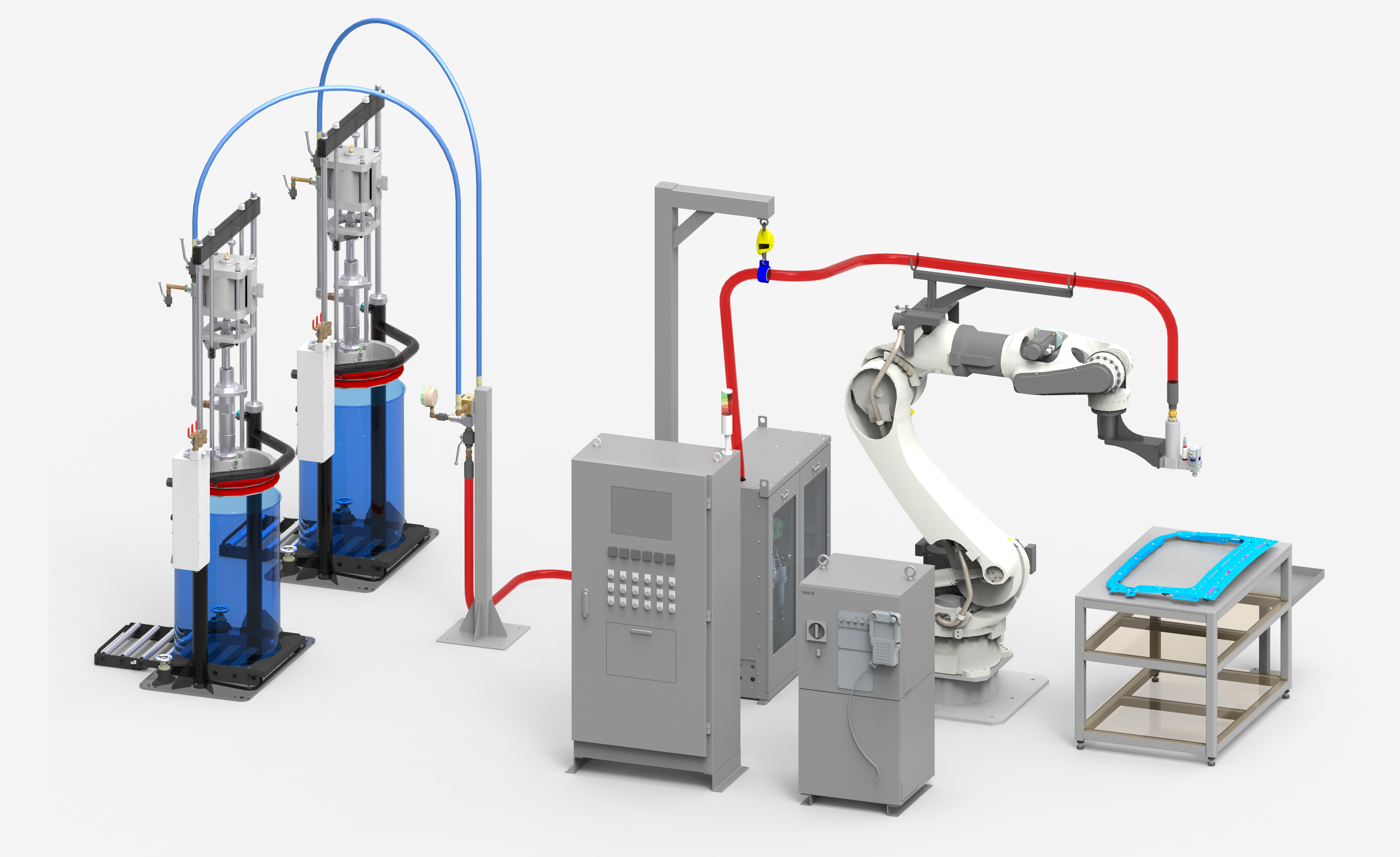

The spread-typed body panel enforcing agent (BPR sealant) is the one-package paste-form product mixing latent hardener, other additives et al, including the epoxy resin as the main component, is spread to the strength-weakened part of vehicle's outer panel by robot or hand-operated gun, and plays the role of panel reinforcement and sound deadening as it is hardened and adhered by the heat of painting dry oven. | |||||

| |||||

|

DOOR(FRT/RR) / T-LID(TRUNK-LID) / T-GATE(TAIL GATE) SIDE(LH/RH) • Generally applying the agent to the central point of the outer panel in the rectangular shape (thickness : 1~1.2t) | |||||

| |||||

| |||||

|

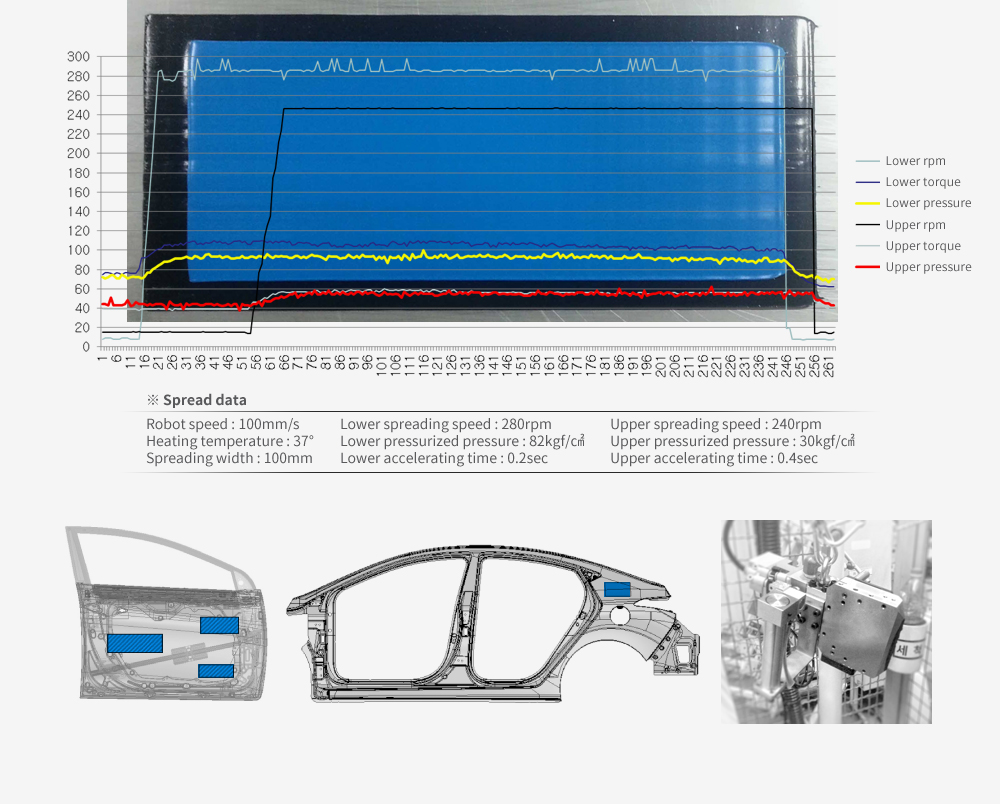

Merits of double-structured BPR • Solving the problem that the outer panel is intensely bended at the boundary of applied part, especially at the low temperature (below -20℃) Merits of Shinhang's double-structured BPR • Double spreading of the buffer agent(rubber) and the upper layer agent(epoxy) • Securing the spread quality of the boundary surface by maintaining uniform thickness | |||||

| |||||

|

|

|

|||

|

• Appearance of the sealant : grey or black-colored paste • Main component : epoxy resin • Hardening rate : 98% or higher • Viscosity : 200,000~300,000 cps • Maximum working pressure : 300 kgf/㎠ • Booster capacity : 100 / 200 / 300cc |

• Automation available • Preventing the panel bending • Enhancing the safety of the vehicle • Able to adjust the spreading area and height • Saving the material cost • Enhancing the corrosion resistance |

||||

| |||||